Broadly speaking, 3D printing has actually experienced something of a reverse evolution of types. It began mostly as an enthusiast and DIY innovation, yet the technology has grown and is understanding its commercial capacity. Software application growths are driving ahead a lot of the major innovation landmarks in 3D printing. In FDM, there have been developments in non-planar printing, with G-code generation software application enabling the printing of rounded lines to decrease ladder impact, eliminate supports for overhangs, and boost upright stamina. A lot of sector rate 1 and 2 vendors have now developed an excellent understanding of the possibilities and constraints of the AM procedures.

Flexible Published Electronics And Their Applications In Food Top Quality Surveillance And Intelligent Food Product Packaging: Current Breakthroughs

As the phone call for more sustainable items becomes louder, we anticipate the 3D printing market to respond appropriately. This can be available in the form of more lasting products such as filament made from recycled or Earth-friendly product. Recycling programs for plastic spools and thrown out 3D published items must also come to be much more usual.

3D imaging is currently the requirement in orthotics examinations, however 3D innovation progressively is a staple in footwear layout as well. Aetrex Worldwide, which acquired 3D-printing foot-support startup Sols in 2017, incorporates the two. A computer vision-enhanced foot scanner called Albert prepares an optimal plan for each customer, after that a printer rejects the Tailored Wall Murals orthotic. In 2017, Adidas presented its Futurecraft 4D footwear that was made using a procedure created by Carbon. And Formlabs developed a material for New Equilibrium called Rebound Material, a springy-but-strong base that supposedly executes much better than foam. All three jobs will certainly use the Vulcan II, a tablet-controlled, gantry-style printer that uses symbol’s exclusive cement-based product mix, called Lavacrete, to construct frameworks.

Castable materials use incredibly great details and hold their shape well, making them perfect for fashion jewelry. This is optimal for LED lights and for showing the inner elements or functions of an appliance or various other item, with other jobs that have actually made use of clear resin including light pipes and prisms. Criterion materials are a terrific, reasonably low-priced way to develop high resolution resin models. Enroll in our e-newsletter to obtain updates on new Creality 3D printers, bargains, and brand-new articles. You can acquire a portable enclosure which can be set up very promptly.

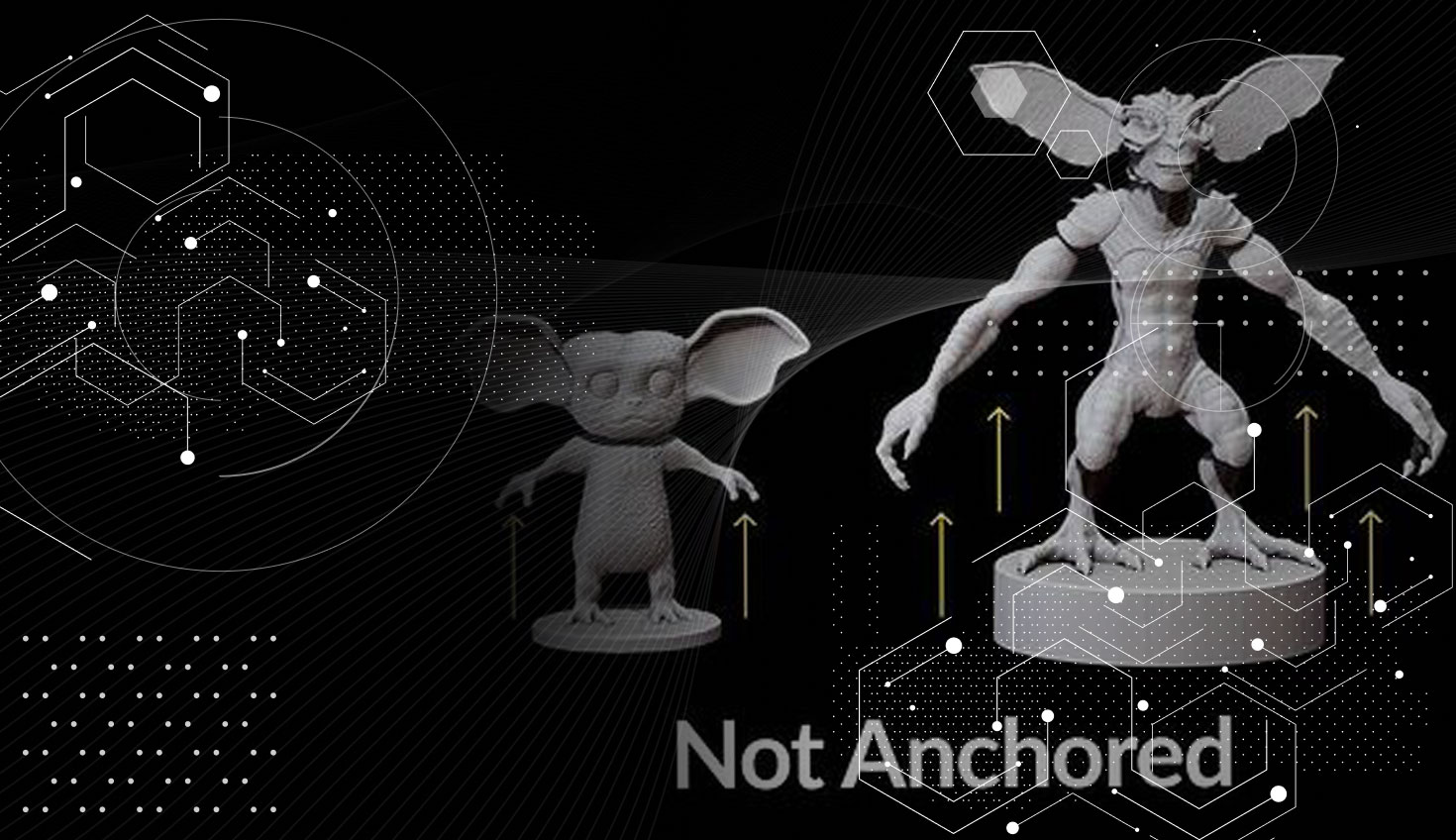

Larger nozzles work best for prints without slim or fine information because they print thicker layers. To anticipate and protect against these difficulties, keep each overview thing in mind throughout your design procedure. Keep in mind when 3D printing that the electronic variation of your layout will have to deal with the legislations of physics when it comes out of your 3D printer’s nozzle. To show that you can attain high-end outcomes economically, we printed each version in this overview with a Molten Deposition Designing printer.

Global Dental 3D Printing Market Size, Future Market Trends in Dynamic Industries (2023-2030 … – salisburyandstonehenge Global Dental 3D Printing Market Size, Future Market Trends in Dynamic Industries (2023-2030 ….

These technologies, integrated with 3D printing, will significantly enhance process repeatability by decreasing the danger of build failures. By discovering the ins and out of the innovation, Boyce found that the very same 3D printer made use of for prototyping could likewise be used to make sure end-use polymer components. Ever since, the technology has become a vital component of Boyce’s service and Bespoke Mural Designs is used for manufacturing applications 90% of the time.

A Basic, Low-cost Conductive Composite Material For 3d Printing Of Electronic Sensors

We saw this trend in the direction of completion of 2022, and we anticipate it to continue as the industry develops. The tasks toward improvement from a typical warehouse to a digital storage facility in order to reduce inventory costs and recognize a spare-parts-on-demand idea will certainly be continued. As AM becomes much more extensively adopted in industry, software will certainly also continue to progress to connect the space and use it to its complete extent.

However, with major metal machine builders now tackling these issues with the improved binder jetting systems and artificial intelligence software program, the developments they make will certainly just drip to the ceramic AM market. The homes of resins, linked with production techniques and the distinct process of 3D printing, will enable the Custom Wall Artwork manufacturing of customer items widespread. Rather than having standard sizes such as tiny, tool, or large, the measurements of consumer items can be, Bespoke Mural Designs many thanks to 3D printing, tailor-made and comply with the distinct account of each consumer. By the end of the years, AM will be a recognized production approach like lots of others before.